What is the NBS Smoke Density Chamber?

“Where there’s smoke, there’s fire.”

Smoke is the product of insufficient combustion of the material. And smoke is the primary cause of death in fires, followed by temperature. Therefore, the smoke production characteristics of the material combustion are important.

The test for measuring the smoke generated from solid materials, using the smoke density chamber, was developed in 1966 by the Fire Research Department at the National Bureau of Standards (NBS). And the test device was developed as NBS Smoke Density Chamber in the past decades.

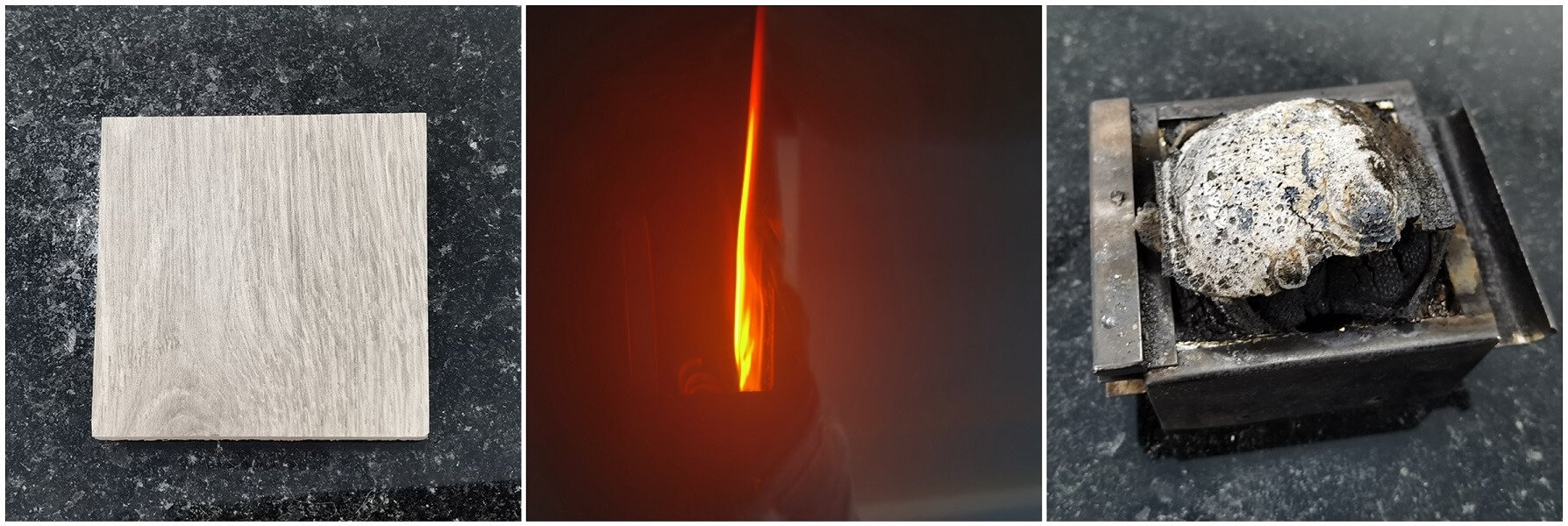

The NBS Smoke Density Chamber measures the specific optical density of smoke generated by the materials using a flat specimen (up to 25 mm thick) exposed to a specific radiant heat source (normally 25 or 50 kW/m2), in a closed chamber with or without a pilot flame.

How’s the NBS Smoke Density Chamber Works?

The principle of the NBS Smoke Density Chamber is to calculate the specific optical density by measuring the light transmission of the smoke as a percentage of the initial light transmission (light transmission, in %) using an optical system built into the chamber. The minimum percentage of light transmission is usually used to calculate the maximum specific optical density Ds.

The formula is, Dsmax=132Log10(100/Tmin).

Tmin is the minimum transmittance during the test.

The NBS Smoke Density Chamber consists of

Test chamber, the internal dimensions are 914mm by 914mm by 610mm, with good anti-corrosion ability.

Built-in optical measurement system.

Radiant heat source.

Data acquisition system.

Operation software.

During the smoke density test, the specimen is mounted horizontally/vertically within a chamber and exposed to the radiant heat source on their upper surfaces at specific levels of irradiance (up to 50 kW/m2). The smoke generated is collected in the chamber, and the attenuation of a light beam passing through the smoke is measured by the photometric system built-in in the chamber. The data and results are collected and calculated by the software.

Application

The NBS Smoke Density Test has been developed as a primary test for assessing the reaction to fire characteristics of materials used in buildings, railways, ships, aviation, and cables.

The involved test standard includes:

Horizontal Conical Heater

ISO 5659-2 Plastic – Smoke generation – Part 2: Determination of optical density by a single-chamber test.

IMO FTP Code Part 2 Smoke and toxicity test

Vertical Furnace

ASTM E662 Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials

BS 6401 Method for measurement, in the laboratory, of the specific optical density of smoke generated by materials

NFPA 258 Recommended practice for determining smoke generation of solid materials

Summary

The NBS Smoke Density Chamber is used for measuring the smoke generated from solid materials and it has been developed into two different radiant heat sources, a horizontal conical radiant heater (ISO 5659-2) and a vertical furnace (ASTM E662) respectively, and with different test procedures.

MOTIS can offer ISO 5659-2 and ASTM E662 configuration smoke density chamber with the corresponding test program. It takes approximately 15 minutes to exchange between two different configurations. Visit our website or contact us for more detail about NBS Smoke Density Chamber.