Flame Test Manikin

Compliance

ISO 13506, ASTM F1930

The Flame Test Manikin uses the manikin to evaluate the performance of the garments or protective clothing exposed to a short flash fire environment. The most important feature is that it can quickly, accurately, and reproducibly simulate the heat exchange between the human body, protective clothing, and the environment under flash fire conditions.

During the manikin test, using a manikin placed in a simulated fire environment with controlled heat flow, burn time, and flame distribution to predict the position and extent of 2nd Degree Burns & 3rd Degree Burns to the human skin, thus assessing the overall thermal protection performance of the garment.

The Flame Test Manikin meets the testing standard of ASTM F1930 and ISO 13506.

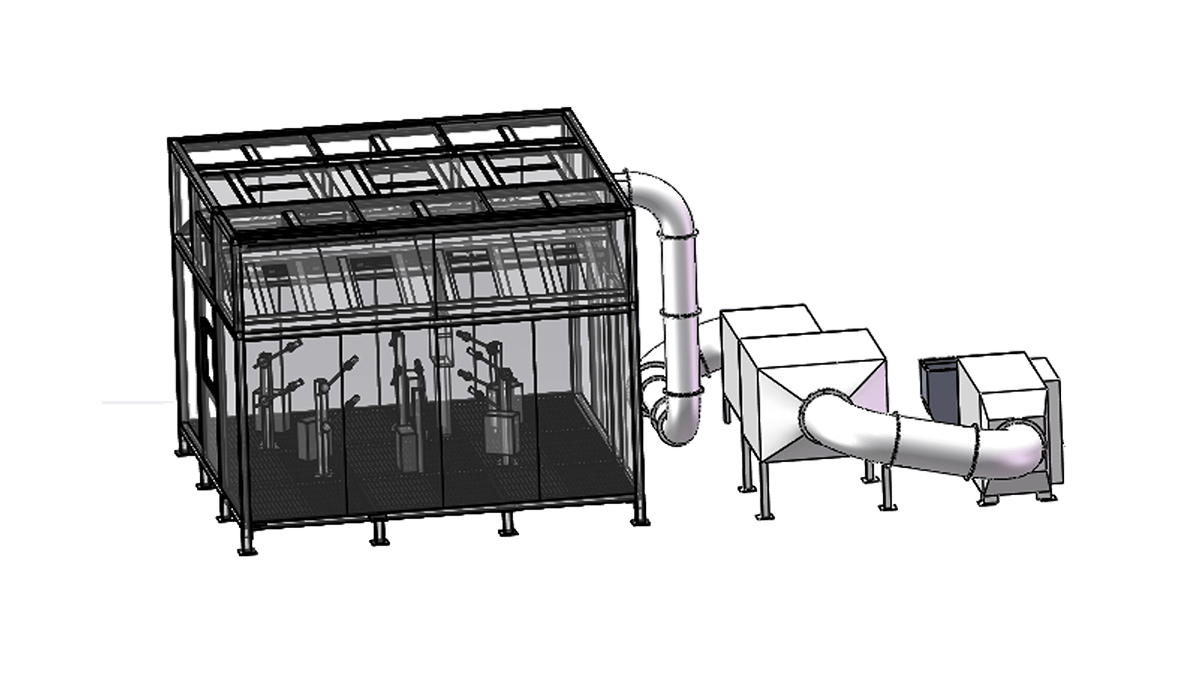

Flame Test Manikin Schematic

Flame Test Manikin Chamber

The Flame Test Manikin consists of

The manikin is US original, body dimension meets ASTM D6240, having a ceramic composite that is completely fire-resistance.

The manikin is of high temperature resistant design, applied to a bare body calibration test at 84 kW/m2 flame intensity and exposed to open flame for no less than 12 seconds.

The manikin skin is uniformly divided into 124 areas, each with a precise copper calorimeter heat sensor.

High temperature resistant metal tubes built into the neck of the manikin to provide support, with sensor cables connect to the surface heat sensors.

Copper calorimeter sensors are with extremely high measurement sensitivity and response time over a measurement range of 0 to 167 kw/m2.

Sensor calibration system, including sensor accuracy calibration and origin position calibration functions.

12 Torch array, consisting of 12 cast iron burners, distributed around the manikin to provide a uniform heat flux to manikin at least 84 kW/m2.

Cast iron burners with the individual gas distributors, as well as adjustment handles and needle valves, with flame protection to ensure that combustion does not backfire.

Burners can be switched on individually or in array to produce a consistent heat output to the manikin.

Each burner is equipped with an ignition system, flow control system that instantly provides the flash flame by means of remote control.

Gas delivery system by means of multiple propane cylinders, connected by means of a manifold, and through a precise pressure regulator to provide a stable pressure to ensure that a uniform flame front onto the manikin.

The modular burn chamber, dimension is approximately 4m (height) x 5m (length) x 5m (width), which is larger than the ASTM F1930 minimum dimension to provide a better test performance.

The burn chamber is fitted with a combustion leak monitoring system that automatically detects propane gas leaks and automatically cuts off the gas supply.

The burn chamber equips with a large high temperature resistant glass observation window to allow the operator to observe and record the flame test manikin.

A fresh air ventilation system is equipped for the burn chamber, which quickly vent smoke and heat from the chamber after a single flame test and replenishes the fresh air into the chamber.

Data acquisition system with simultaneous acquisition of 124 imitation copper calorimeter sensors, with individual sensor acquisition frequency of no less than 10 times/second.

Standard test software, containing sensor monitoring, sensor calibration, standard test procedures, automatic calculation of test data and report export, which can automatically calculate test data such as burning degree and burn area.

Motis Flame Test Manikin Software

ASTM F1930, ISO 13506 Test Procedure

01 Instrumented Manikin

02 Dressed Manikin

03 Manikin Test

04 After Test

Motis provides a complete turn-key package for Flame Test Manikin in accordance with ISO 13506 or ASTM F1930, including burn chamber, test manikin, control system, ventilation system, operation software.

Contact us to get a brochure and quote.